In early 2020 African Bee Keepers Ltd were approached by Pear Dairy in Mbarara Uganda to Assist in designing and setting up a beekeeping project to work with their existing dairy farmers, Nine (9) zones was selected for the project in the Mbarara District.

African Beekeepers Ltd would provide the project with three years’ consultancy services on management of the beekeeping project

African Bee keepers ltd prepared the project proposal for the project which was to operate 1000 langstroth bee hives, each dairy farmer was to get a number of bee hives. The project would also operate a team of field extension personnel equipped with motor bikes, the field extension staff were to be trained by African bee keepers Ltd on modern bee keeping management practices.

An altar modern honey processing and packing factory would be set up in Mbarara to handle all the project honey.

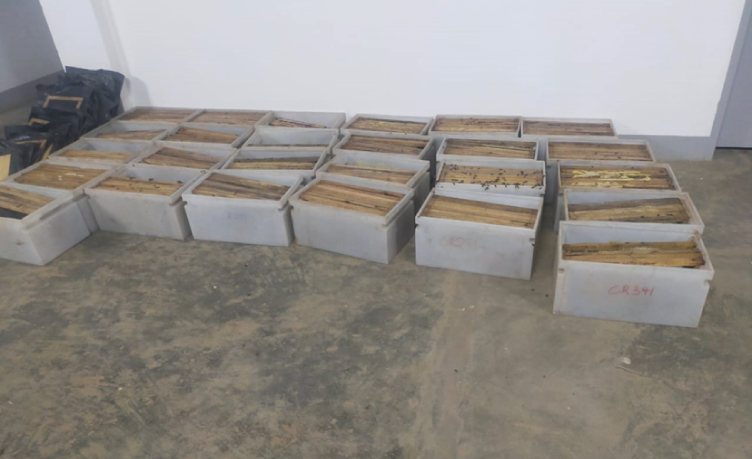

In August 2020 the project commenced, African Bee keepers Ltd supplied 1000 langstroth bee hives in fully knock down form Which were assembled on site in Mbarara, also supplied were 1000 metal bee hive stands and 50 bee keepers kits and 450 plastic frame crates.

Being the pandemic year, trainings to assemble the hives had to be conducted virtually, through zoom by African bee keepers Ltd.

The team of field extension staff underwent extensive training on langstroth bee hives management, the trainings where conducted both virtually and onsite in Mbarara by African Beekeepers Ltd. In September 2020 the bee hives were issued to the well selected farmers and who were involved together with the Pearl Dairy extension staff in selecting and set up of the apiaries. the bee hives begun colonizing almost immediately, by the July 2021, 80 % of the bee hives were colonized. As the colonies developed in the bee hives, super boxes were installed.

Several field visits have been conducted by African Bee Keepers consultant team, this being part of the ongoing trainings for the field extension staff.

In March 2021 The altar modern honey processing and packing facility was assembled and tested to process capped honey combs which was harvest from the project bee hives, once the honey was extracted it would be packaged and labeled by a fully automated honey packaging machine. A team of personnel were recruited and trained to operate the factor which is now fully operational.

Training field extension staff

Beehives in trapping zone

Training extension staff in the field on inspection.

Field extortion motor bike equipped to carry hives and super boxes.

Harvested capped combs.

The Pearl Dairy Mbarara beekeeping team.

Training field extension staff

Training field extension staff

Training field extension staff

Installing beehive stands.

Apiary site setup.

Harvesting capped combs.